Rethinking Contracting Norms for a Modern Defense Industrial Base

Stop sacrificing speed, resiliency and talent in the pursuit of controlling costs.

At the Creative Disruptors in the Desert event, there was a discussion on encouraging tech companies to do business with DoD, while also balancing the use of legacy practices focused on ensuring “reasonable profits.” This leads us to question whether how we do business today is likely to deliver the best results. More broadly, it raises the question of whether DoD’s focus on cost is appropriate given the current challenges.

Reasonable Profits

Consider the following scenario: DoD released a Request for Proposal and there are two major competitors bidding on the contract.

Company A: A traditional defense prime bids $1B with an 8-10% profit margin.

Company B: A non-traditional defense company bids $500M with a 50% margin.

The source selection team may look at Company B with skepticism. How could they do the same work for half the price? They must be low bidding to win the contract? Potential reasons could be:

Using more efficient digital processes.

Created modular software that allowed for greater reuse.

Attracted better talent to complete the work faster.

Invested billions to develop a platform/pipeline for many commercial and government applications.

It should be a no-brainer for the government to go with Company B at half the cost yet there are significant process barriers given the perception of excessive profits. There is currently little chance that a Contracting Officer could justify going with Company B to its business clearance board. There would be fear of an article in the Washington Post that “Company B is Price Gouging the DoD at 5X the Profits of Established Primes”. Certain senators would call for hearings and GAO audits to unpack what must be fraud, waste, and abuse and seek to void the contract.

Even with the most courageous organization and logic in its favor, the use of weighted guidelines as currently constructed would constrain the ability to provide adequate rationale. If this was a cost contract, the limit would be 15%.

Crafting business arrangements that yield higher margins attracts more companies to bid on future contracts. Increased competition motivates existing defense companies to better control costs. Ultimately, the DoD wins with lower costs and gains the ability to fund other priorities.

With modernized contracting approaches, a contracting officer could also take larger considerations into account. Maybe they would experiment with different business arrangements to assess what delivers the best value for their organization (and their unique needs). Maybe they would consider National Defense Industrial Strategy goals and assess how different approaches could be employed to meet them.

Cost versus Fixed Price

This dilemma ties into the renewed debate over Cost Plus vs Fixed Price contracts. The traditional prime typically operates with cost plus contracts. They’ve invested in robust cost accounting systems where DCMA and DCAA reviews their books on a regular basis. That provides the government with greater confidence that the prime isn’t gouging a naive contracting officer to get a fair and reasonable price.

Non-traditional defense contractors prefer to only operate on fixed price contracts. Given their technical specialization, they often have a better understanding of the likely costs, risks and opportunities. This runs counter to the large primes or integrators who may subcontract work out to 20 different vendors and thus incur a lot of uncertainty. They also prefer fixed price as it does not require establishing a laborious and costly cost accounting system that requires employees to use timecards and manage multiple charge codes.

Some in the government have a preference for fixed price contracts (see Frank Calvelli and Andrew Hunter) which should make non-traditional contractors more attractive. A fixed price contract transfers cost, schedule, and performance risk to the vendor. They become more incentivized to control costs, which often includes delivering sooner. Conversely, under cost plus contracts, companies are incentivized to put more people on the contract and for each month of delays, they can bill the government for more work. More delays = more revenue with a fixed percentage of fees (profits).

Labor Rates

A related issue is labor rates. DoD has organizations that audit proposed labor rates from a vendor and use different sources of data to assess the adequacy of the rate justification. Attracting technical talent is a known defense industrial base challenge. Defense contractors have highlighted that rigid labor categories, challenges in adjusting for inflation and compensation caps make it hard to attract and retain talent from the commercial side. One survey had 80% of industry respondents reporting that it was “somewhat” or “very” difficult to compete.

Restricting the ability for defense primes to hire top engineers and other tech talent due to archaic processes impairs the capabilities of the defense industrial base. Leading tech companies appreciate the importance of recruiting top talent and paying them well because they know they are worth 3-10X the value of an average engineer.

Consider the following notional teams:

20 average software engineers at $150K each = $3M.

3 high performing software engineers at $300K, 10 average at $150K = $2.4M.

4 unicorn software engineers at $500K = $2M.

While one can debate the salaries, benefits, and factors, which team would you choose to go with? Who do you think would be more efficient, produce higher quality work, and generate better value?

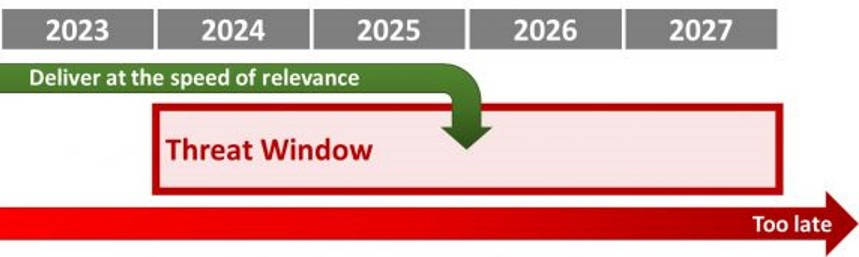

Speed

The unhealthy focus on keeping profits low and wages average is also misaligned with DoD’s need for speed. The Deputy Secretary has been on record multiple times saying that DOD must field capabilities faster and there has been substantial literature on the potential for a Taiwan invasion in the near future, yet the contracting process has little focus on this critical factor.

What does it benefit DoD to have a slew of cheap, low-profit generating companies in its industrial base who are delivering at average or lower timelines? How does this drive better outcomes? How does this allow us to operate at the speed of relevancy?

Instead, we need to push for reform of these archaic processes that are anti-capitalist and counter productive. We need to start having more detailed discussions of these issues across the DoD, Congress, and industry to align strategic goals with agency processes. We need a better understanding of each other’s perspectives, incentives, and environment. Many of the cost controls were put in place decades ago to protect the government from being bilked by expert company negotiators which was right for the time. As we move into a more services-centric and commercially driven paradigm, we need to revisit our business practices.

Competition is the best way to decrease costs and increase innovation.

We need to regrow the defense industrial base and encourage leading American tech companies to get involved in national security. Heavily regulated contracts with 8-10% margins are not going to do that. If companies can deliver a vastly improved capability at the same price, or the same capability at a much-reduced price than its competitors, it shouldn’t matter if they’re making huge profit margins.

The government benefits by lower costs, high quality solutions, and a larger industrial base to compete on future contracts. We need the traditional defense prime contractors who have decades of experience and infrastructure to produce systems at scale along with non-traditional companies who bring new talent and tech to national security.

What’s your perspective on these issues? Please comment below to contribute to the conversation so we understand all views and potential solutions.

Defense Tech and Acquisition is a reader-supported publication.

To receive new posts and support our work, consider becoming a free or paid subscriber.

Pete and Matt, once gain you’ve highlighted an important issue in contracting with some great examples. For all commercial items DoD procures, this should be at fixed prices regardless of the profit margin. This is how commercial companies do business (without government-funded IRAD). The other reason a commercial company can price lower with higher margins is that the cost base using much higher commercial volumes is completely different than building bespoke items for DoD. If DoD is procuring a consumer item, the volumes would be in the millions compared to perhaps thousands for DoD which implies incredible efficiencies in manufacturing and supplier component costs.

The bar is "What's fair and reasonable to the taxpayer?" The better question is "What's fair and reasonable to the warfighter?"